This project demonstrates a system integration designed for large-scale commercial kitchens. By leveraging a 15-inch HMI and RS-485 serial communication, we have established a centralized monitoring and control network for 6 Siemens Variable Frequency Drives (VFDs).

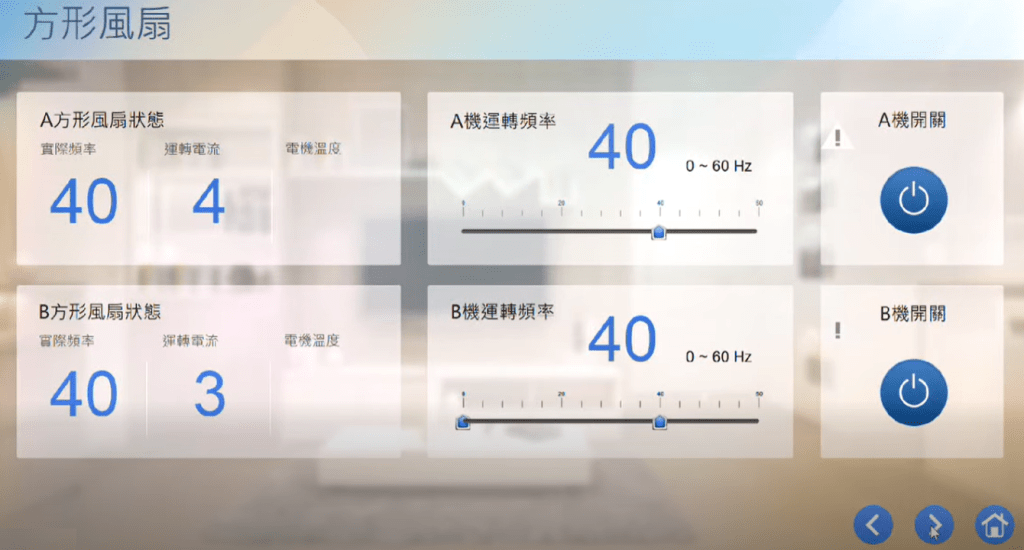

- Communication: Using the Modbus RTU protocol, the system allows for the remote control of VFD operations while simultaneously retrieving real-time diagnostic data, such as operating current and frequency status.

- Multi-Zone Airflow Management: The system manages independent exhaust and supply fans across different zones (e.g., frying areas, general kitchen, and dining halls). This ensures efficient smoke removal and maintains a clean, comfortable environment for both staff and customers.

- Energy Efficiency: By implementing VFD control, motor speeds are optimized based on actual demand, significantly reducing energy consumption compared to traditional fixed-speed systems.

- Friendly Visualization: The large-format HMI features a user-friendly dashboard and floor plan view, enabling facility managers to monitor system performance and zone status at a glance.

發表留言