Precise monitoring of VOC (Volatile Organic Compound) emissions is essential for the flexible packaging industry to meet environmental standards and optimize production. FrankMEC provides a comprehensive Pitot tube-based air volume detection system, specifically engineered for Gravure, Flexo, Lamination, and Coating processes.

Key Features:

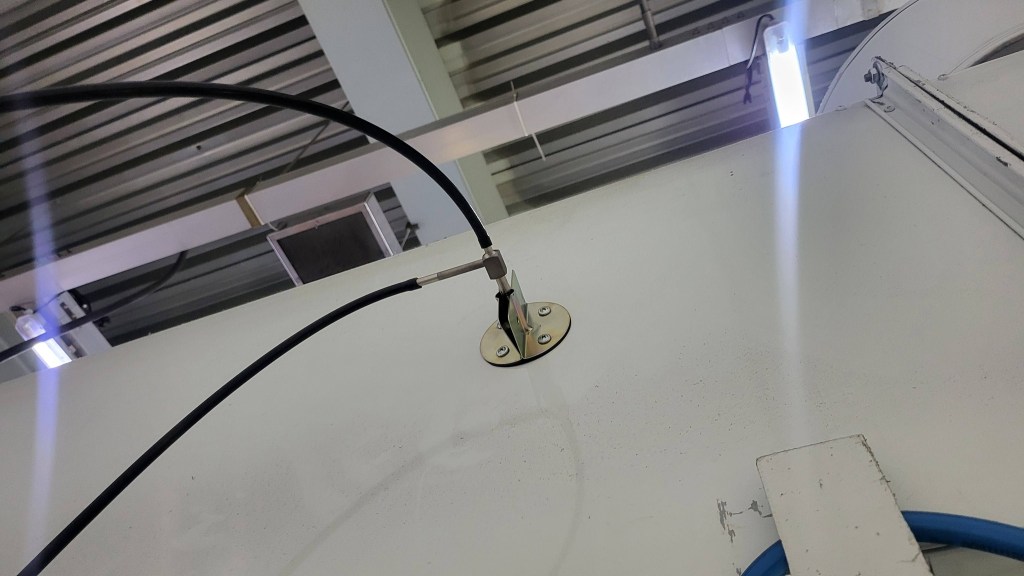

- Robust & Solvent-Resistant: The stainless steel Pitot tubes are designed to withstand the harsh environments of organic solvent emissions common in the converting industry.

- Signal Integration: The system converts physical differential pressure into a 4-20mA signal, captured by high-precision data acquisition modules for real-time analysis.

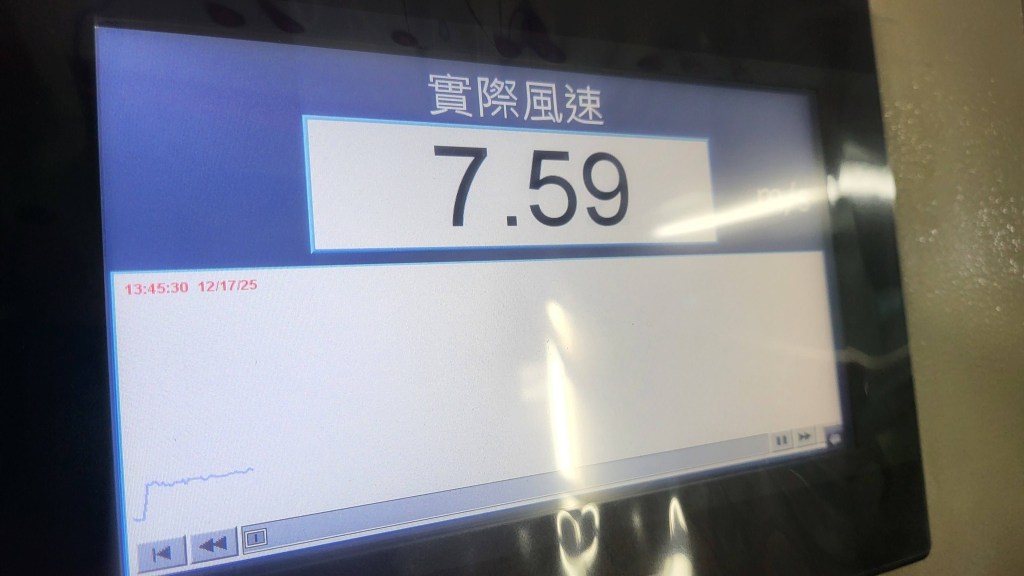

- Real-time Visualization: The HMI displays instantaneous wind speed and calculated air volume, featuring live trend curves for intuitive monitoring.

- Process Optimization: Airflow control is a critical parameter affecting solvent evaporation and lamination quality. Data transparency allows operators to fine-tune process parameters, ensuring consistent quality and efficiency.

- ESG & Compliance: In Taiwan, managing VOC emissions is a mandatory requirement. Our system provides the data foundation for material management and ESG reporting, offering complete history logs and database integration.

FrankMEC delivers a turnkey solution for data collection, recording, and database management, empowering your facility with data-driven manufacturing.

發表留言