Using Siemens Technology Objects (TO) to control third-party drives like Rexroth provides a robust and flexible, common in high-end European machinery. Below is the optimized integration workflow.

I. Hardware Configuration & Synchronization

- GSDML Integration: Import the Rexroth GSDML file into TIA Portal to establish the PROFINET node.

- Isochronous Mode (IRT): For high-performance motion control, ensure the PROFINET network and the Drive/PLC cycle are synchronized via IRT to minimize jitter.

II. Communication via PROFIdrive Telegrams

The system relies on the PROFIdrive standard.

- If the Rexroth drive supports standard telegrams (e.g., Tel 1, 3, 5, 105), the integration is straightforward.

- If custom mapping is required, use the Data connection via Data Block method.

III. Data Connection via Data Block (The “Actor/Sensor" Interface)

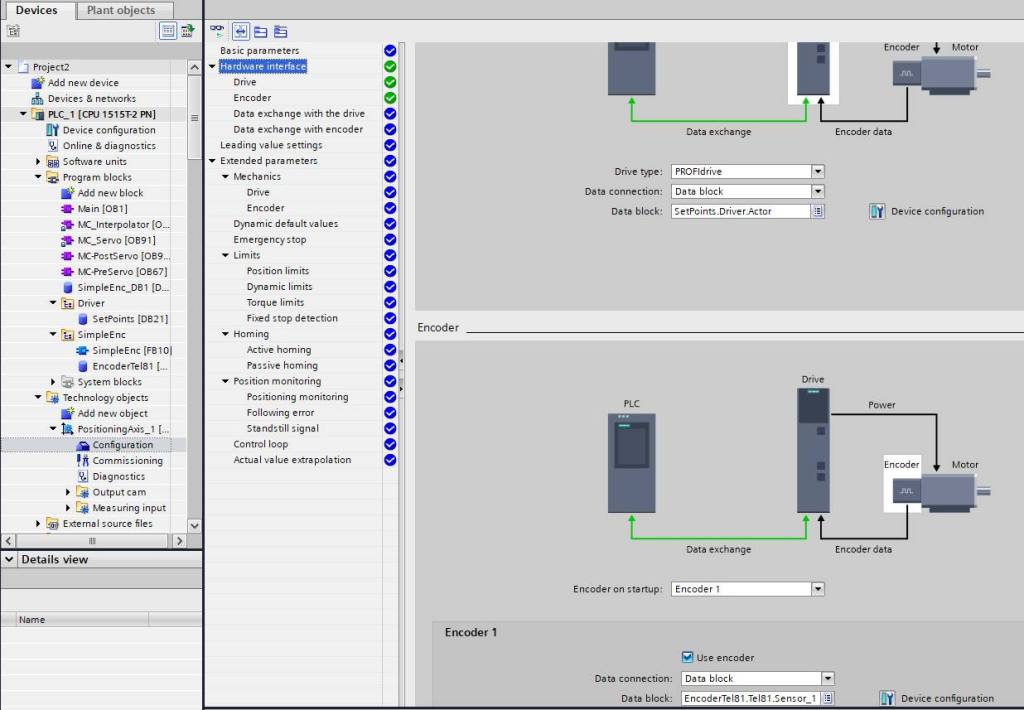

As shown in your configuration screenshot, this method decouples the TO from the physical I/O:

- Interface DB: Create a Global Data Block using Siemens system data types (e.g.,

PD_TEL1,PD_TEL3). - TO Hardware Interface: Set the “Data connection" type to “Data block".

- Mapping:

- Link the Actor (Drive output) to the SetPoint structure in your DB.

- Link the Sensor (Encoder input) to the ActualValue structure in your DB.

- Data Exchange: Use a communication block (often within the Isochronous OB) to copy the raw PROFINET I/O data from the Rexroth drive into the designated Data Block.

The Siemens TO acts as a “Driver Layer." By standardizing the interface through a Data Block, the motion control logic remains independent of the hardware brand. This allows engineers to combine the best of both worlds: Siemens’ powerful motion control system and Rexroth’s high-performance drive units.

發表留言